Welcome to Sarvsource Projects LLC

- ssprojects67@gmail.com

- 8182706463

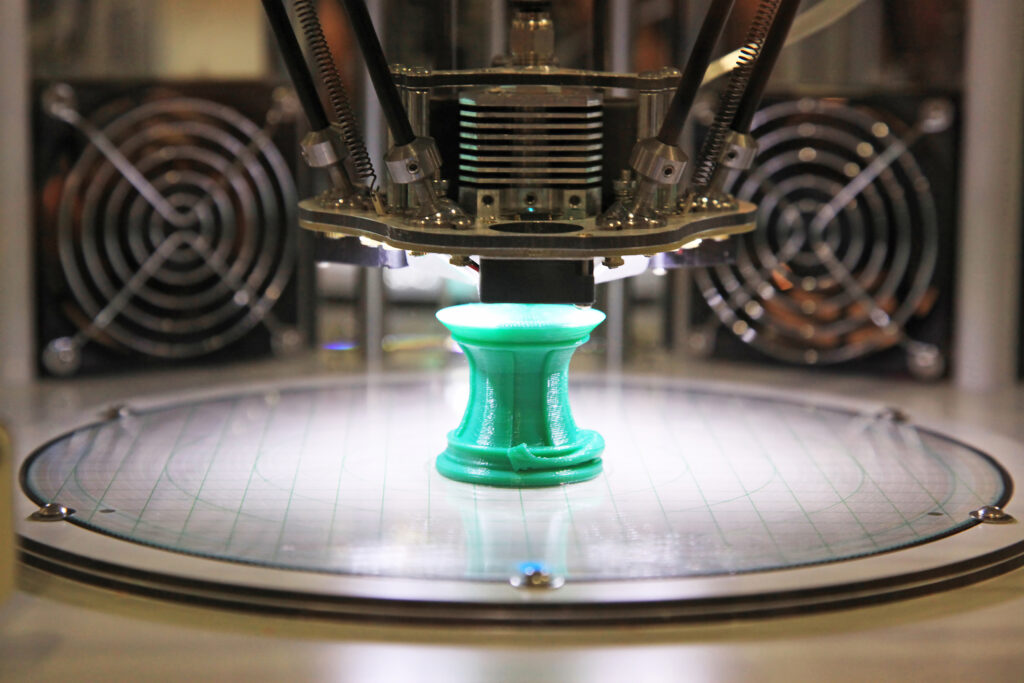

3D Printing

Service

Stereolithography (SL) is the pioneering and most established method in layered manufacturing, and it remains capable of generating conceptual prototypes in a brief timeframe of a few hours or days. Components created using SL can be swiftly utilized to produce hollows in silicone molds, function as templates for investment or plaster casting, and can also be effortlessly painted for assessments of form and fit. SLA materials have progressed significantly, and we now provide high-temperature and composite-based resins. To address high-resolution requirements, we fabricate parts using customized SLA machines and lasers capable of building layers as thin as 0.002 inches, resulting in overall tolerances of 0.005 inches. Completed parts can be readily painted, polished, dyed, machined, shielded, and possess sufficient strength for tapping and incorporating inserts.

Ultra High Definition

Layer Thickness: 0.002” Z

Build Sizes: 11” x 11” x 12” or 20” x 20” x 20”

Standard Definition

Layer Thickness: 0.005” Z

Build Sizes: 10” x 10” x 10” or 20” x 20” x 20”, or 25.5” x 29” x 21”

Materials

Components created using Stereolithography Apparatus (SLA) can be rapidly utilized to generate voids in silicone molds, function as models for investment or plaster casting, and can also be effortlessly painted for dimensional and functional analyses.

POST Process

High Detail (HD):

- Layer Thickness: Ultra-thin (0.002”)

- Build Sizes: Large (up to 11” x 11” x 12”) or Extra Large (20” x 20” x 20”)

Standard Detail (SD):

- Layer Thickness: Thinner (0.005”)

- Build Sizes: Various (10” x 10” x 10”, 20” x 20” x 20”, or 25.5” x 29” x 21”)

Finishing Options (SLA Post Processing):

- Metal Coating: Nickel over copper plating, chrome plating, vacuum metalizing

- Painting & Texturing: Painting, soft touch

- Polishing & Threading: Polishing, tapping, threading

- Insertion & Customization: Insert or helicoil installation, pad printing