Welcome to Sarvsource Projects LLC

- ssprojects67@gmail.com

- 8182706463

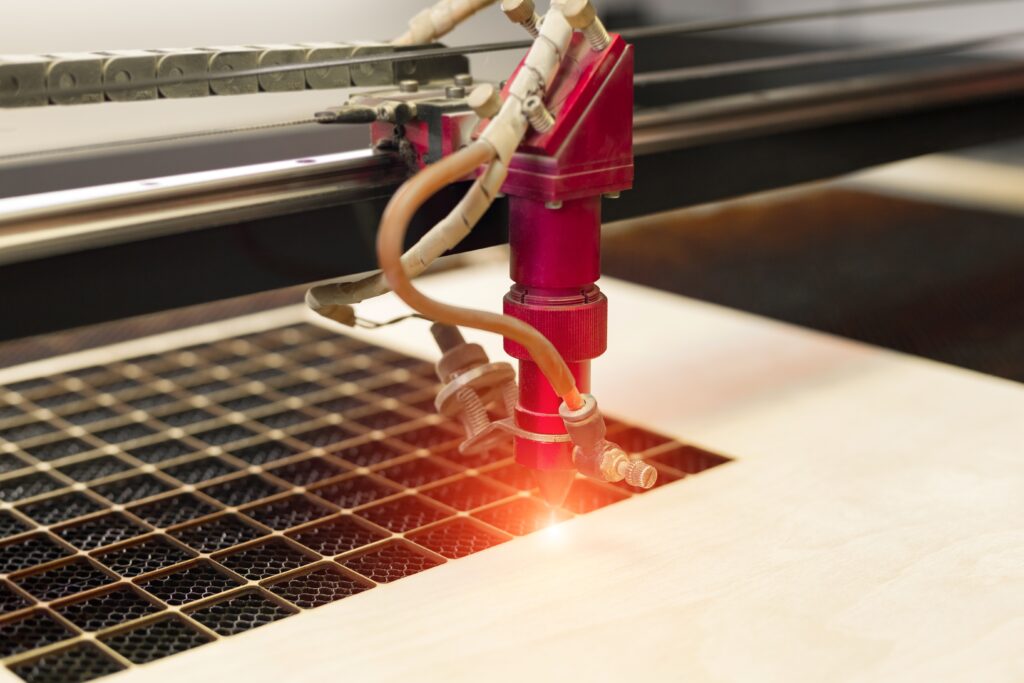

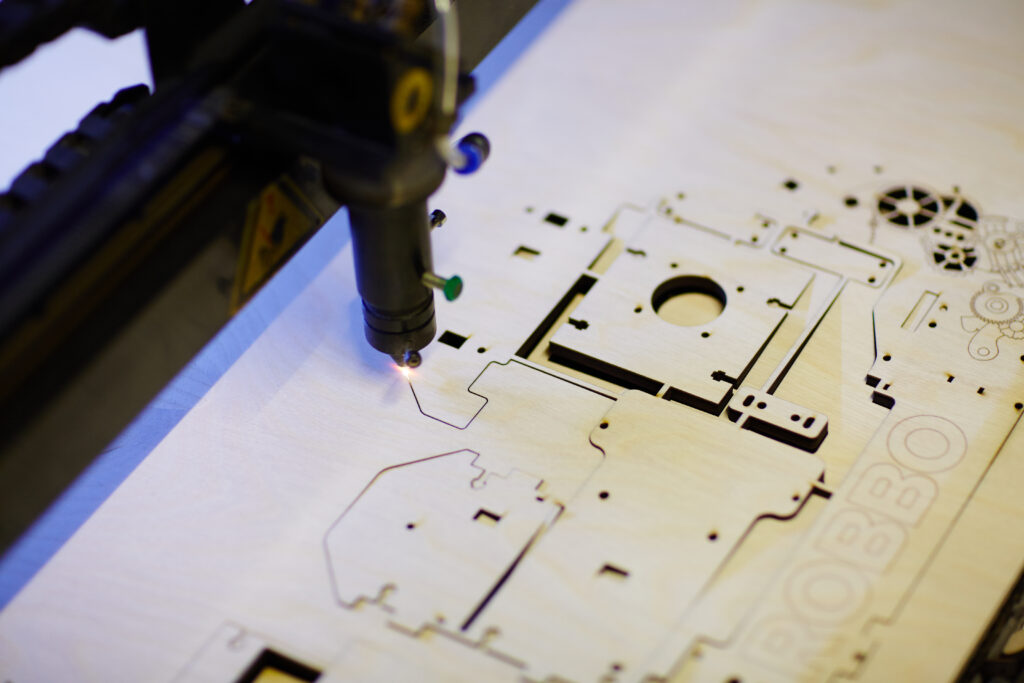

Sheet Metal Prototypes (Laser Cutting & Water Jet Cutting)

Service

The fabrication of sheet metal components and structures involves one or several of the following techniques. Each service can be individually chosen for part manufacturing. Here are some methods: laser cutting, waterjet cutting, electrical discharge machining, die stamping, shearing, punching, threading, forming, adding triangular reinforcements, texturing, and more. A variety of materials and thicknesses are offered.

Materials

Metals: Aluminium, Beryllium-copper, Brass, Carbon steel, Nickel-based alloys, Phosphor bronze, Stainless steel

Metal alloys: Aluminum, Beryllium copper, Brass, Carbon steel, Nickel alloys, Phosphor bronze, Stainless steel

POST Process

Post-Processing: Chemical Film Application, Anodizing, Plating, Painting, Polishing, TIG Welding, Threaded Insert or Helical Coil Installation, Assembly (instead of SHEET METAL POST PROCESSES)

Material Compatibility: Broad range of commercially available metals (instead of Materials: All commercially available materials)