Welcome to Sarvsource Projects LLC

- ssprojects67@gmail.com

- 8182706463

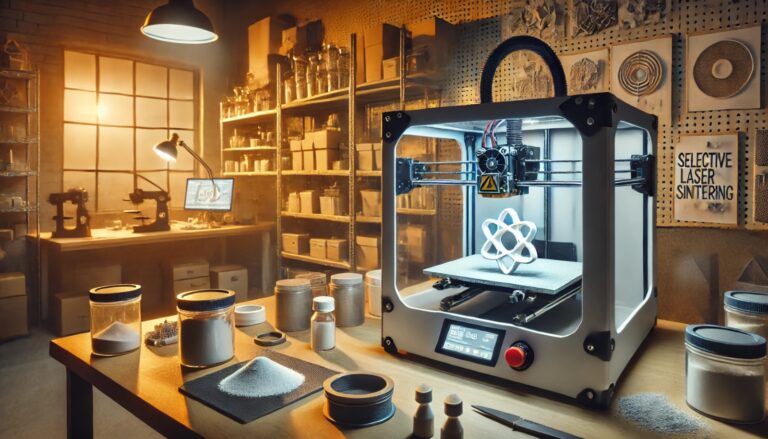

Selective Laser Sintering

Service

Advanced Laser Melting (ALM), a fabrication technique, excels at creating rapid prototypes or limited-quantity production runs. Compared to Stereolithography Apparatus (SLA) parts, SLS components boast superior strength and noticeable weight reduction. The absence of mandatory support structures allows for the construction of complex assemblies and intricate, large geometries. Our single-piece build capacity reaches an impressive 29″ x 16″ x 23″. Finished parts can be readily smoothed with sanding, customized with paint or dye, or enhanced with EMI shielding, plating, and machining. We provide a selection of materials, including glass-filled variants, Nylon 12, and carbon-fiber composites.

Materials

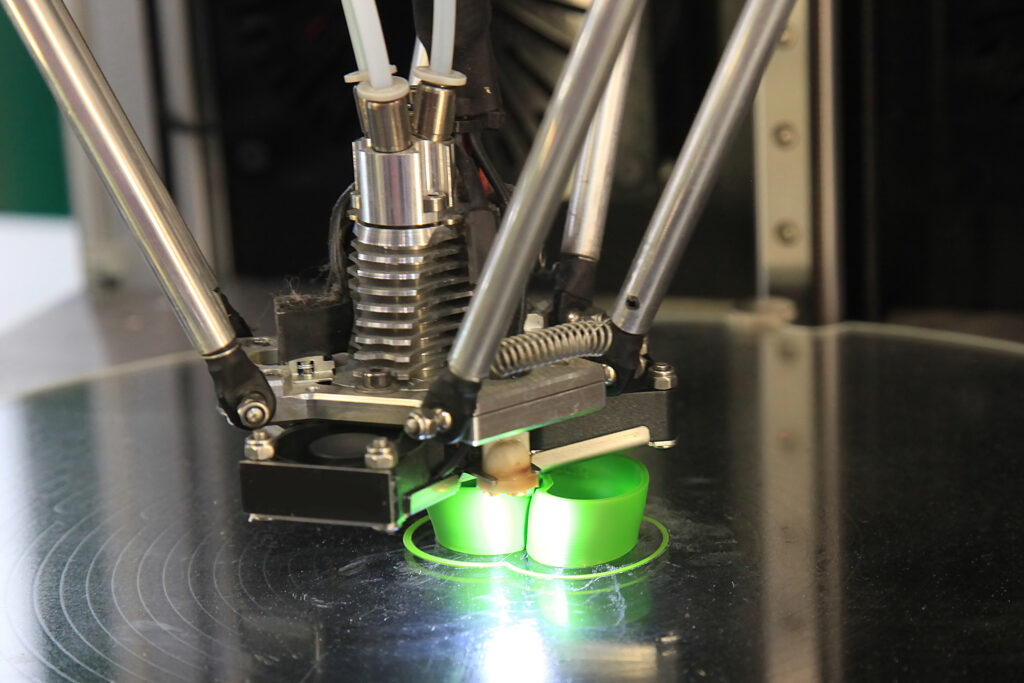

Additive manufacturing (AM) technique, Selective Laser Sintering (SLS), utilizes a high-powered laser to bond (fuse) various nylon-based powders to create functional prototypes rapidly or for limited-volume production.

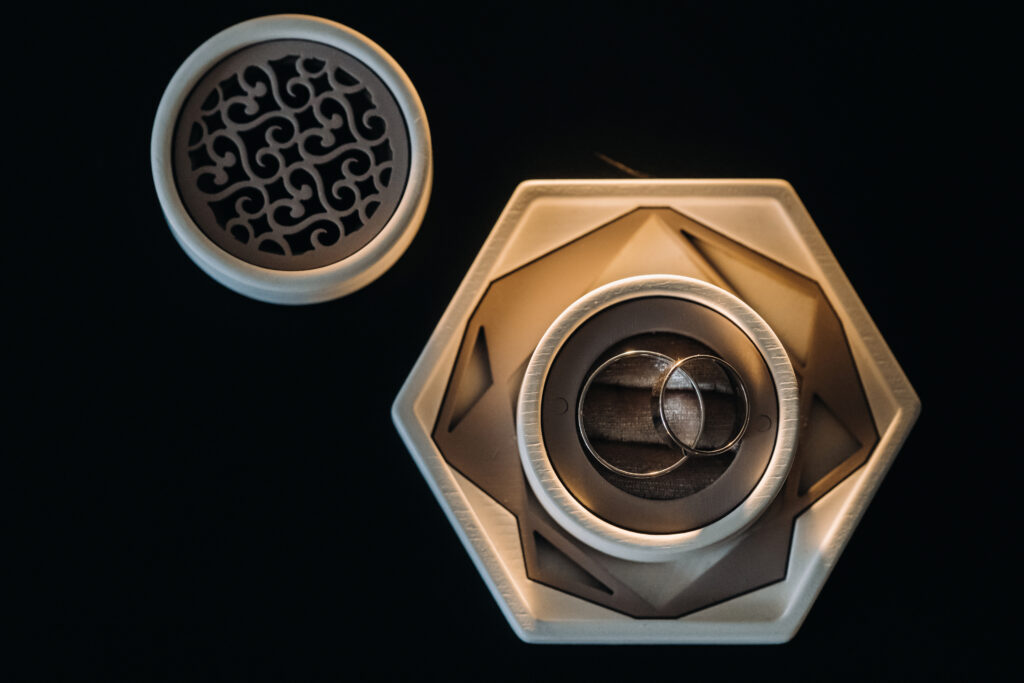

POST Process

Development & Manufacturing

Model Thickness: 0.004 inches (Z-axis)

Build Dimensions: 29 inches x 16 inches x 23 inches

Finishing Techniques

Electroless nickel plating with copper undercoat, electromagnetic shielding, coloring, coating, sealing / impregnation, vibratory deburring, decorative chrome plating, physical vapor deposition, thread tapping, thread cutting, insert or helical thread insert installation, mechanical processing, final assembly.