Welcome to Sarvsource Projects LLC

- ssprojects67@gmail.com

- 8182706463

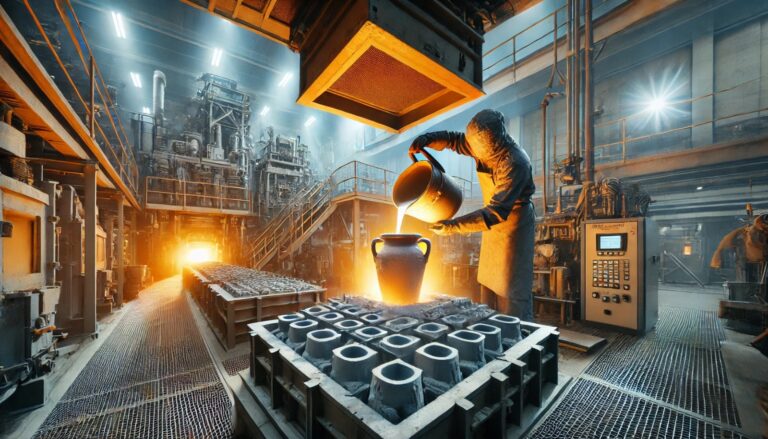

Investment Castings

Service

The complexity of your part design determines the prototyping method. Investment casting excels at intricate shapes and offers a wide selection of alloys (materials) like aluminum, zinc, magnesium, steel, and even Ti-6AI-4V. It starts with creating a wax model, later eliminated using molten metal. Parts cast in this way have tolerances between .007″ and .040″, but machining or EDM can achieve tighter precision.

For part geometries optimized for production die casting and volumes under 200 units, plaster casting shines. This method involves crafting a master pattern (either machined or SLA) used to create a cost-effective, single-use plaster mold. The molten metal is then poured into this mold using gravity. Ideal for prototypes and low-volume production, plaster casting allows for quick and affordable mold modifications. Tolerances achievable range from .015″ to .045″. Compatible materials include aluminum, magnesium, and zinc.

After either process, the resulting parts can undergo various finishing treatments such as machining, EDM, painting, polishing, powder coating, sandblasting, chemical filming, and more.

Materials

Aluminum Magnesium Steel Ti-6AI-4V

POST Process

Finish CNC, Painted, Polished, Finish EDM, Powder Coated, Sand Blasted, Chem Film, Nickel Plated